Hybrid eXtreme X-Clamp Fix Tutorial(Repair Kits)

Introduction

Clicks: 628215

Author:

| Error codes that can be fixed with this method: | ||

|---|---|---|

| Primary | Secondary Error code | |

1RLOD 1RLOD | E74; |

|

2RLOD 2RLOD | 0013; 0012; 0011; | |

3RLOD 3RLOD | 0001; 0020; 0021; 0022; 0100; 0102; 0103; 0110; | |

4RLOD 4RLOD | ||

Last Update: 10th Mar 2012

Video Tutorials:

1) Hybrid Fix Video Tutorial by WorldFormula2) XBOX 360 RROD Ultimate Hybrid Fix Part 2 DIY on Youtube, by GamerGuy51, Thx!

Other Languages:

![]() Italian/ Italiano(Updated, link fixed, works again now!)(Thanks Ivan@ilops.it)

Italian/ Italiano(Updated, link fixed, works again now!)(Thanks Ivan@ilops.it)

![]() German/ Deutsch

German/ Deutsch

If you need help just post a topic on our Forums

Official Resellers for eXtreme Hybrid Uniclampâ„¢ Repair Kits

Resellers:

Europe:

![]()

Germany: Xboxexperts.com Official Store

![]() North America:

North America:

USA: Xboxexperts.com Official Store

Start of the Tutorial: Materials & Tools

Materials:

- *Rubbing alcohol + wipes or thermal compound remover (arcticlean)

- Tape

Tools Used:

- Scissors

- Phillips screwdriver

- Wrench

- *Sandpaper (around 400 grit)/Sanding tool/ Flat surface sanding tool

- Drilling machine/Dremel or similar

- *Drill with bit capable of drilling 5mm hole through metal

- *Torx T8 driver/*Torx T10 driver

*If you bought an "eXtras+Tools" Kit all these will be included already

Note: All tools and parts are sold on our store so if you need anything take a look, you shouldnt find it anywhere else cheaper, there are even mosfets, caps and other hard to find spare parts for the xbox.

Warning: Dont use the kit if your console is not broken! While it makes perfect sense to use this kit to prevent errors we do not recommend it. The simple reason is every time the mainboard is moved it flexes and this by itself can cause damage, so you risk that your console might break from it. So dont fix anything that isnt broken.

Introduction

Hello everybody.

Some time has passed since I released "Wilhelm's Improved X-Clamp Fix" and I mentioned a while ago that some others and I were working on the so called "Hybrid" version of my fix. Basically it started out being a mix of my method and RBJTechs, so imagine "Wilhelm's Improved X-Clamp Fix" but with the screws going all the way through the metal chassis instead of securing them only to the bottom of the motherboard. We had a prototype of this method running after a week, which seemed to be working more or less fine at the time. We still wanted to improve on the fix and had talks about the 360 and why the regular X-clamp fixes often fail again down the road. Eventually we came to the conclusion that one of the main problems was that the force is always being applied to the chips in an uneven way. With the stock setup, the force in applied downwards from the top over the chip dies, and the force is only countered by the small area under the center of the chip below the motherboard where the middle of the x-clamps press up. With the normal x-clamp replacement, most of the pressure is being applied right on top of the dies which presses downwards in the middle of the CPU and GPU chips. There is no upwards support under the chips to keep them from flexing.

One of our main goals was to find a way to apply equal pressure to both the top and bottom of the CPU and GPU chips to prevent them from flexing in either direction. The big improvement here from the stock setup would be that MS applies all the underside pressure to one tiny spot under the middle of the chips, while we wanted to spread that pressure over the whole are of the chip to equal out the downward force coming from above (heatsink and credit card pieces). While we were brainstorming and experimenting with new methods, Jimbobjim released his sandwich method which was a bit of an improvement from the stock method and sparked our idea to re-use the x-clamps, but in a modified and improved way. You can check out our dev-library to view pics from our early ideas and methods that we tried out.

Next we spent some time testing new prototypes and looking for materials that we could build squares out of to use as pads against the underside of the motherboard below the chips. These pads would evenly counter the downwards pressure coming from above and also prevent any flexing from occurring on the chips. Our goal was to find an economical material with the right consistency that the average user would have easy access to. Expensive thermal gap pads could be used, but would be extremely expensive even to test out and would not generally be the easiest thing for the average person to find. We experimented with several different materials based on cotton, paper, weird blue foam, felt, and even the stock RAM thermal pads. Finally we found that common craft foam (4mm thick) was one of the best materials to use because it is very cheap and also is able to apply pressure to the motherboard without damaging any components on the board. Another alternative to foam was paper handkerchiefs folded up into squares the right thickness.

Proof Of Concept

We had successfully repaired several rod units and thought we were basically done, when by chance I noticed some flexing in the middle area of the mainboard that seemed weird to me so I took some measurements and discovered some of the reasons for the flexing. The discovery was that the standoffs and outer lip of the metal chassis in which the motherboard rests were not completely level with each other. The 2 standoffs are exactly 0.75mm too high, this might not seem like much, but since they are supposed to be 3mm high this is about 1/4th more which is definitely noticeable with a straightedge or level. In addition to that we also discovered that middle area of the chassis where the X-Clamp bolts screw down are about 0.5mm lower than the rest of the chassis, causing the mainboard to be pulled down in the center as soon as the screws are tightened. This puts the entire mainboard under extreme stress which explains pretty much why there is such a wide range of errors that are not related to the CPU or GPU.

1) This flexing could also explain why certain errors occur more frequently than others. Because of the flexing in different areas of the mainboard, You can divide it into three flexing zones in which the mainboard is flexing the most in zone 1 and the least in zone 3.

Zone 1:

The most frequent error codes are 0102 (0100;0101;0103 as well)and 0020. These are GPU and CPU related errors mainly. 0020 can also be caused by the RAM in rare cases. About 80% of the errors fall into this category, which makes sense as the solder balls under the CPU and GPU experience the most flexing of all. This is caused by the x-clamps flexing the area extremely in addition to the natural flexing caused by the metal case layout. Zone 1 is the area right under the CPU and GPU.

Zone 2:

The next most frequently occuring error codes are E74, 0022 and 0110, which are usually either RAM or ANA/HANA chip related. Sometimes E74 and 0022 can also be GPU related depending on the trace. Since the RAM and ANA/HANA chips are close to the GPU they can be affected by the Zone 1 flexing, in addition flexing caused from the two standoffs.

These may not occur as often as the Zone 1 errors, but still make up approximately 12.5% of the overall error codes.

Zone 3:

The Zone 3 area experiences the least amount of flexing versus the other 2, but can still make up about 7.5% of the error codes. The related error codes are E73, 0021, E79(if hardware related), E71(if hardware related). The components effected by Zone 3 flexing are the Southbridge, ethernet chip, NAND and the entire motherboard to some extent. Since the NAND and ethernet chips are not BGA (ball grid array) chips like the Southbridge, GPU, CPU, HANA, etc, they are a bit more resistent to the flexing.

*Remember that the percentages were not taken from definitive statistics, they are just numbers that we estimated based on our own experience.

Here is a little graphic that shows the three zones...

The following is a graphic comparing the flexing schematics of the stock setup versus our newer hybrid fix.

These flexing issues are only part of the problem and as you read on will find that in conjunction with the following issues, its no wonder the 360 has had such a high failure rate to date.

2) Many of the error codes are commonly blamed on the heat buildup inside the system. As far as I know this is also the cause Microsoft was betting on since they have added better heatsinks to combat the ring of death. Thermal design experts from Nikkei Electronics in Japan decided to analyze the 360's heat radiation system and a few critical flaws with the cooling system....

Click here to read their full article.

- That there was a temperature gap of 22C between the exhaust and room air, "When designing consumer products, it is common to seek a temperature gap of around 10C between exhaust and room temperatures," the thermal design expert said.

- The maximum wind speed of the exhaust air is only 1.1 meters per second, only 1/2 to 1/3 compared to normal desktop PCs produce. The expert noted, "The amount of switched air is slightly in short considering the chassis' size (309 x 258 x 83 mm3)."

- It takes only 5 minutes of gaming for the GPU heatsink to reach 70C, a thermal gradient of about 10C/min and after 15 minutes of play, the GPU heatsink can reach temps near 100C.

On a hot summer day it is possible for internal temps to get high enough to damage some components (over 100C), however heat is only a secondary issue as without the flexing it would not be causing nearly as many problems that it currently does. The heating process causes further flexing and puts more stress on the solder balls. During thermal cycles, the mainboard and solder balls expand and shrink a bit, but without the flexing, the heat would have a much smaller impact on the console's reliability. The excess heat just exaggerates the flexing problems and puts extreme stress on the solder joints of the BGA chips.

Why "Drill-Free" Fixes dont work!

The problem with drill-free fixes is, the mainboard basically flexes up and downwards from heat, so if you dont fix it to the chassis, it will do that really bad because nothing prevents it from moving, this is what makes it worse with the regular X-Clamp Fixes, it can swing around, the X-Clamps are usually at least attached to the case so thats even better than that...

We have been looking into that issue ever since and got some prototypes in work but best results you can only get by drilling, you need to make modifications to the faulty chassis setup, if you leave it as flawed as it is you might as well not do anything...

3) The next issue many people blame problems on is the use of leadfree solder and "cold" solder joints because of its use. Starting July, 2006, the E.U. set strict environmental guidelines called the RoHS Directive, which banned the use of lead in any products marketed towards children. For nearly 50 years, the standard solder used was a tin and lead combo which had a melting point of around 183C. The new lead-free solder now needs temperatures of at least 217C. In fear of damage from over-heating, it is speculated that Microsoft's engineers most likely opted for the low-end of temp profiles needed for re-flow. Reflow experts from Manncorp did an extensive investigation into the quality of the lead-free solder joints in the 360 and found that with an x-ray they could actually see solder balls that did not look like they had been re-flowed properly in the first place.

Click here to read their full report. They also discovered that perhaps because of the chips being thicker right where the dies are, that the solder balls right under them in the middle are the ones most prone to not being re-flowed properly from the factory because they were not getting enough heat. Perhaps Microsoft knew of this and thought applying extra force upwards on the center of the chips would help the bad connections, but obviously their fix didn't work as well as planned.

Some people have also speculated that when the temperature of the solder balls change rapidly, for example after turning the 360 off, they can over time can develop tiny cracks and loose stability which can lead to eventual failure of the unit. If the tiny cracks don't lead to failure, then possibly tiny fragments solder break off when the cracks are formed leading to points being bridged and shorted. There is a specific error code for shorted out solder balls in the GPU - RAM area which is 0020. Some also claim that this error can occur when you remove the entire GPU, but we are speaking about sealed stock systems so we dont have to regard this. In reality this is a pretty unlikely scenario because cracks might form, but most likely not actually break into fragments. I have never heard of someone actually proving this, or ever finding any chunks of solder in his console, so we can pretty much rule this out.

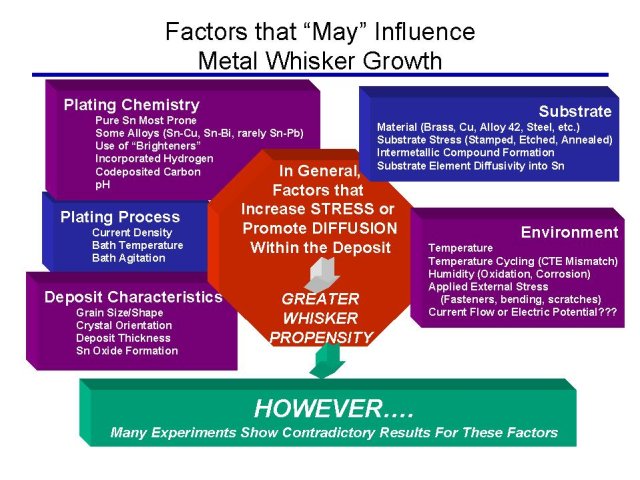

My guess is that this certain errorcode at least might be caused by a phenomenon called Tin Whiskers. Tin whiskers are little crystals which can grow up to 1mm annually. 1mm per year might not sound like much, but if you regard that there is less than 1mm space in between each solder ball then it makes sense because a single whisker could grow under normal circumstances enough to cause a short circuit within less than a year. There are many different metals they grow on like tin, zinc, gold, silver etc. The lead-free solder contains zinc and tin which are already something that should open our eyes, however there is something else that fits even better for the 360.

There are certain factors that support the growth of these crystals and they fit the 360 perfectly as said before. The first factor is "Externally Applied Compressive Stresses such as those introduced by torquing of a nut or a screw "(NASA) which we have here thanks to the pressure the solder balls are taken under, especially the ones in the center. Another factor is "Bending or Stretching"(NASA) and as I explained before we get much more flexing and bending than we need, so another match. The last factor is "thermally induced stress"(Wikipedia) and thanks to the hot running GPU, this matches the conditions inside the 360 as well.

Tin whiskers are famous for causing a lot of electronic failures. A famous example is the Galaxy IV satellite which failed in 1998. This was the reason why NASA started researching on this topic as well. There are many more examples, just take a look at

some of the failures caused by tin whiskers... Tin whiskers are not new and have been know of since the 1940's and the only known fix was adding lead to the solder which seemed to stop tin whiskers for nearly 50 years. Scientists are experimenting with new solder mixes that can resist the growth of tin whiskers, but so far nothing has been found to work as good as lead did. I must point out though that so far there have been no proven examples of tin whiskers occurring in the 360. It would probably require a high powered microscope or x-ray device to spot the actual whiskers.

We hope you enjoyed reading this "little" proposal :)

Now we will go on with the actual fix for the numerous issues we pointed out here...

Notice: The Tutorials have been done many times and were often successfull, however we cannot guarantee the success and so dont take any responsibility for any damages that might be caused by it, you do it on your own risk!!!